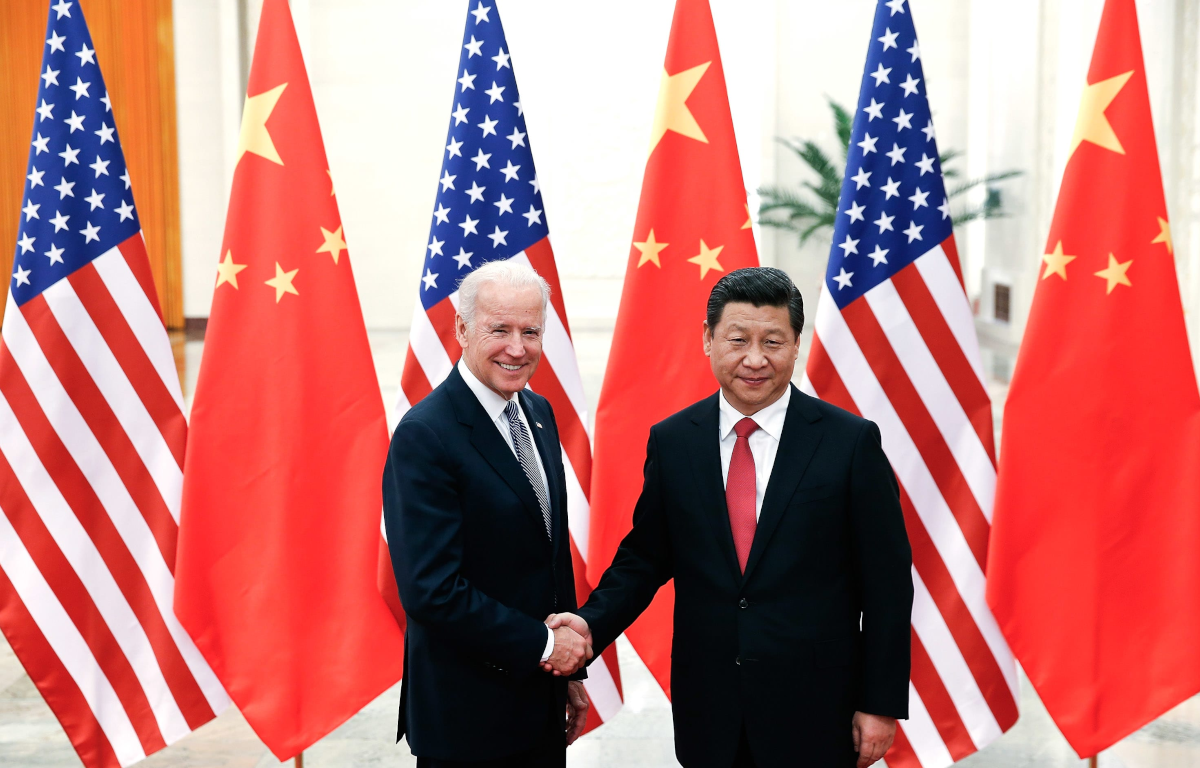

One significant catalyst for these supply chain alterations has been the ongoing trade tensions between China and the United States. The imposition of tariffs on Chinese goods escalated operational costs for numerous American firms. Consequently, many began exploring alternative supply chain sources as a means of mitigating these financial risks.

The COVID-19 pandemic laid bare the fragilities within global supply chains. China’s extensive lockdowns, factory shutdowns, and transportation disruptions had ripple effects throughout the world. It underscored the importance of risk mitigation and spurred businesses to seek ways to fortify their supply chains against future disruptions.

China’s remarkable economic growth has precipitated escalating labor costs. While this signifies an improved standard of living for Chinese workers, it has rendered low-cost manufacturing in China less appealing to foreign corporations. Consequently, many firms are contemplating the relocation of their manufacturing operations to countries with lower labor costs.

Countries such as Vietnam, India, and Mexico have emerged as appealing alternatives to China for manufacturing. They offer advantages such as lower labor costs, proximity to major markets, and, in some cases, preferential trade agreements. Moreover, advances in automation and robotics are diminishing the labor cost advantage traditionally linked to China.

The advent of technology, particularly in data analytics, has empowered companies to optimize their supply chains more effectively. Predictive analytics and AI-driven insights enable businesses to make informed decisions about inventory management, demand forecasting, and supplier selection. This optimization not only reduces reliance on a single source but also enhances overall supply chain resilience.

Many governments are actively promoting diversification within supply chains. In response to the COVID-19 pandemic, several nations have introduced incentives for companies to reshore or nearshore their production. These policies can offer financial incentives and decrease risks associated with disruptions in global supply chains.

Share this: